ECM 1.1 -3 PREDICTIVE MAINTENANCE AND CONDITION MONITORING BY MEANS OF VIBRATION ANALYSIS 300W

Learning objectives:

- Recording of machine condition in real time using vibration analysis

- Recording of vibration data and analysis of frequency spectrum (FFT)

- Investigation of various fault patterns:

- Analysis of alignment errors

- Analysis of imbalance in the drive system

- Analysis of bearing damage

- Analysis of gearbox damage

- Classification of fault patterns and parameterization of warning and alarm levels in condition monitoring

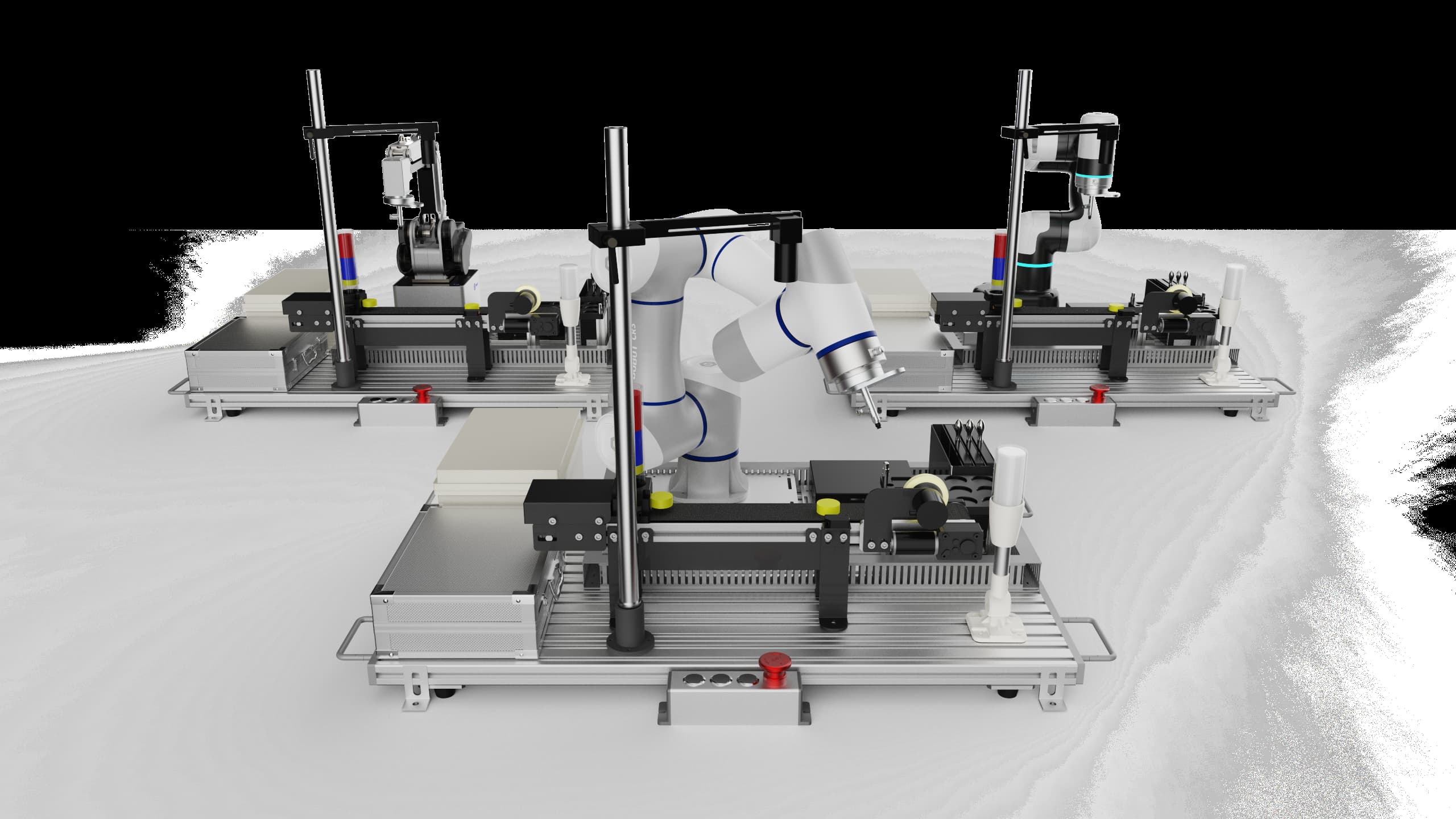

Condition monitoring supplies information about various drive parameters in real time. This provides insight into the current condition of the drive or machine. In so doing, condition monitoring enables precise fault identification, preventive action, maintenance interval optimisation and downtime reduction, and renders production operations more reliable. Predictive maintenance and condition monitoring by means of vibration analysis 300W.

Learning objectives:

- Recording of machine condition in real time using vibration analysis

- Recording of vibration data and analysis of frequency spectrum (FFT)

- Investigation of various fault patterns:

- Analysis of alignment errors

- Analysis of imbalance in the drive system

- Analysis of bearing damage

- Analysis of gearbox damage

- Classification of fault patterns and parameterization of warning and alarm levels in condition monitoring