Yaskawa

Automation & Robotics Solutions

Founded in 1989, Yaskawa Motoman is a leading industrial robotics company in the Americas. With more than 600,000 Motoman industrial robots, 25 million servos and 35 million inverter drives installed globally, Yaskawa provides automation products and solutions for virtually every industry and robotic application; including arc welding, assembly, coating, dispensing, material handling, material cutting, material removal, packaging, palletizing and spot welding.

Our product line includes more than 150 distinct industrial arm, delta and SCARA robot models, plus a full-line of pre-engineered “World” solutions that are complete application-specific robotic systems that include robot, process and safety equipment. Combined with our sister and partner companies, we support robotic solutions throughout the world.

Our proven track record of delivering industry leading quality, innovation and customer satisfaction can help you exceed your automation goals.

Yaskawa Motoman is backed by a powerful parent, Yaskawa Electric Corporation of Japan. Since 1915, Yaskawa Electric has demonstrated a passion for automation by developing specialized solutions to help customers increase efficiency, improve quality, boost productivity, and deliver outstanding ROI. As one of the world’s largest manufacturers of industrial robots, Yaskawa Electric has offices in 30 countries and approximately 15,000 employees worldwide.

Our sister division, Yaskawa America, Inc., Drives & Motion Division, is a manufacturer of various control products, AC servo motors and drives, and inverters.

Yaskawa Motoman Mission Statement

Efficiently deliver high quality, innovative robotic solutions that help our customers and partners to be competitive globally, and to provide the highest level of customer satisfaction in the automation industry.

Yaskawa Motoman Facilities

In addition to our main headquarters and manufacturing facilities for The Americas, Yaskawa Motoman also has an extensive network of regional support centers staffed with experienced professionals dedicated to providing you with timely, skilled support. Worldwide assistance is also available through our sister companies across the globe and via the combined resources of our parent company Yaskawa Electric, manufacturers of robots and inverter controls. Yaskawa Motoman has a growing roster of regional support centers strategically located to serve our growing customer base.

Yaskawa Motoman’s goal is to provide total customer satisfaction, the kind of world-class customer support you expect from your preferred automation supplier.

United States

United States

Yaskawa America, Inc.

Motoman Robotics Division

Miamisburg, Ohio

Contact info | Map | Virtual Tour

- Yaskawa Motoman’s headquarters in Miamisburg, Ohio, is home to the majority of our employees.

- Standard Solutions Group: responsible for our popular “World” solutions and other standard robot products

- Research and development team

- Spare parts and production inventory

- Automation Group (AG): responsible for custom-designed robotic solutions; including fixtures, tooling, conveyors, PLCs, off-line programming and other peripheral equipment.

- Customer Satisfaction Team

- State-of-the-art training facility

- Corporate activities, including sales and marketing

Detroit Regional Center

Rochester Hills, Michigan

- Complete application engineering, training, customer service and sales support

- Robot system demonstrations and application development

- Key focus on integrated robot workcells for welding, material handling, material removal and assembly

- Computer simulation feasibility and time studies

Los Angeles Regional Center

Irvine, California

- Complete applications engineering and sales support

- AutoSorter manufacturing

- Robot system demonstrations and application development

- Spare parts

- Training Center

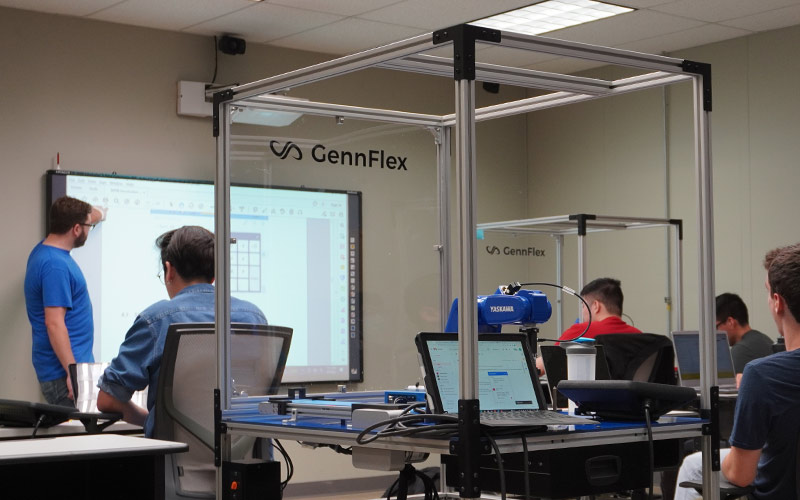

STEM Robotics Solutions

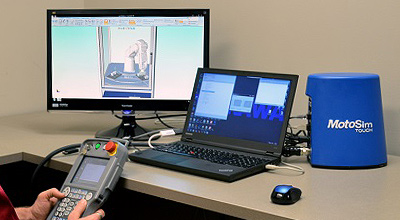

each robotics programming using the same equipment deployed in factories around the world. Featuring standard industrial-grade components and comprehensive academic tools, portable robot modules facilitate education and training, and can be easily customized to fit specific curriculum and classroom layouts. A fully functional production environment can also be simulated with MotoSim® EG-VRC. This powerful education software package enables offline robot programming (OLRP) and virtual 3D simulation of industrial workcells in a safe, virtual setting. Similarly, K-16 school groups can benefit from MotoSim Touch, a PC-based offline programming and simulation tool that allows students to toggle between a virtual programming pendant or a hardware pendant.

Online STEM Robotics Learning

Web-based LMS provides best-in-class STEM robotics education. This comprehensive STEM-aligned curriculum will provide your students with the academic core standards and 21st century skills required for careers in advanced manufacturing.

Certification

Yaskawa Academy offers three certification programs:

- The Train the Trainer Program is designed for instructors of K-12 students, career tech and college undergraduates. It provides the ability for schools to develop a student-based robotics certification course with focus on core robotics skills, or to expand an existing mechatronics robotics program.

- The Modified MERIT Program is designed for instructors of K-12 students, career tech and college undergraduates. It provides the ability for schools to develop a student-based robotics certification course with focus on core robotics skills, or to expand an existing mechatronics robotics program. It also offers the ability to upgrade to the MERIT program.

- The MERIT program is designed for instructors of educational institutions and to support workforce development certification with industry. It enables instructors to deliver the same curriculum and instructional model as Yaskawa Academy to local manufacturers.

Advancing Workforce Development

Equipping tomorrow’s workforce is a team effort. Our industry experts work together with our strategic partners, educational institutions and local officials to enable career pathways in robotics for future success.

Regional Partners

Discover high-quality, comprehensive STEM and educational solutions

Forward-Thinking Education

Unique program trains future innovators

The Exciting and Expanding World of Robotics

Career paths, market outlook and where to start

STEM Education & Workforce Development Brochure

Align workforce development with industry leaders – Download PDF

Workforce Development Partnership

Sinclair works with Yaskawa to offer certification

The Challenges of Making Giant Robots

Jeremy Fielding visits Yaskawa Motoman to learn about the Yaskawa MH900 robot.

Meet a Welding Engineer

WunderSTEM’s Mister C visits Yaskawa Motoman to learn about robotic welding.

Webinar: Workforce in Action

Learn how manufacturers can help educational institutions optimize their training facilities and curriculum to better prepare the workforce of the future.

Equipment

Yaskawa Robots for Education

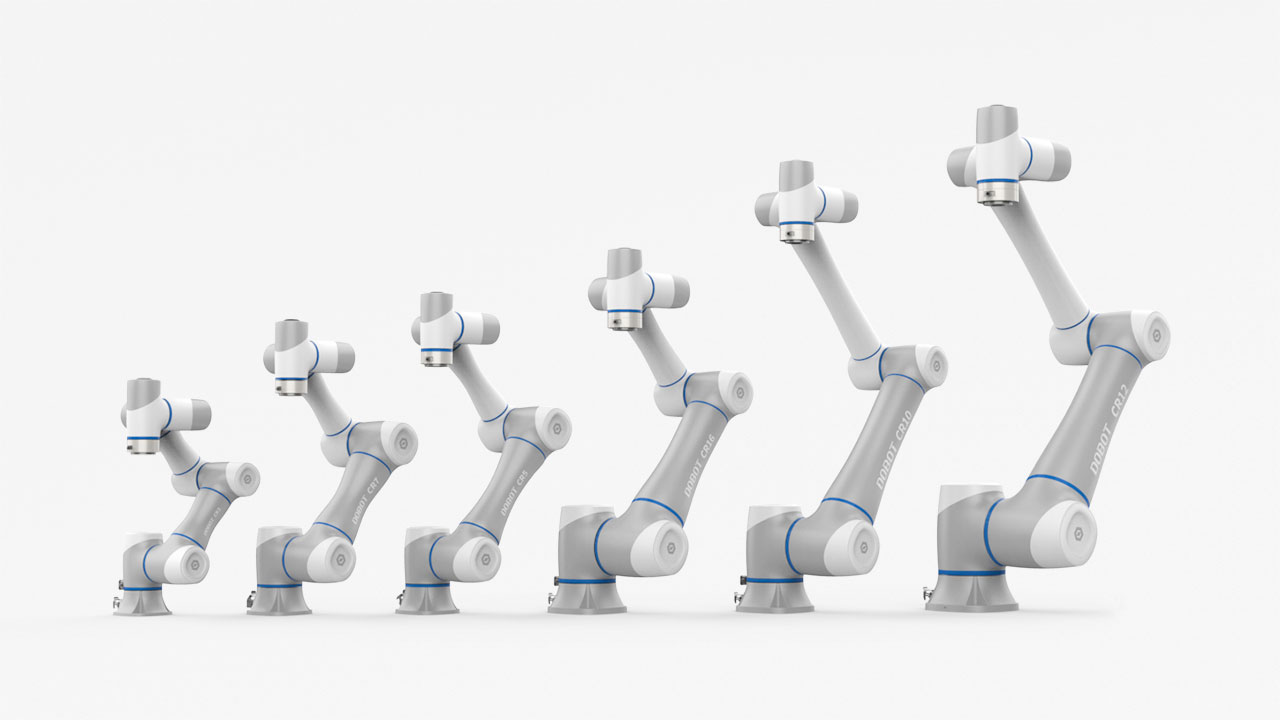

Building an adaptive workforce trained in Industry 4.0 technologies is more important than ever. To address talent gaps and create a relevant labor pool, companies and educational institutions are implementing the same robots and machinery used throughout the industry into their training facilities. Popular robots include: Yaskawa’s MotoMini, GP4, GP8, AR700 and HC10.

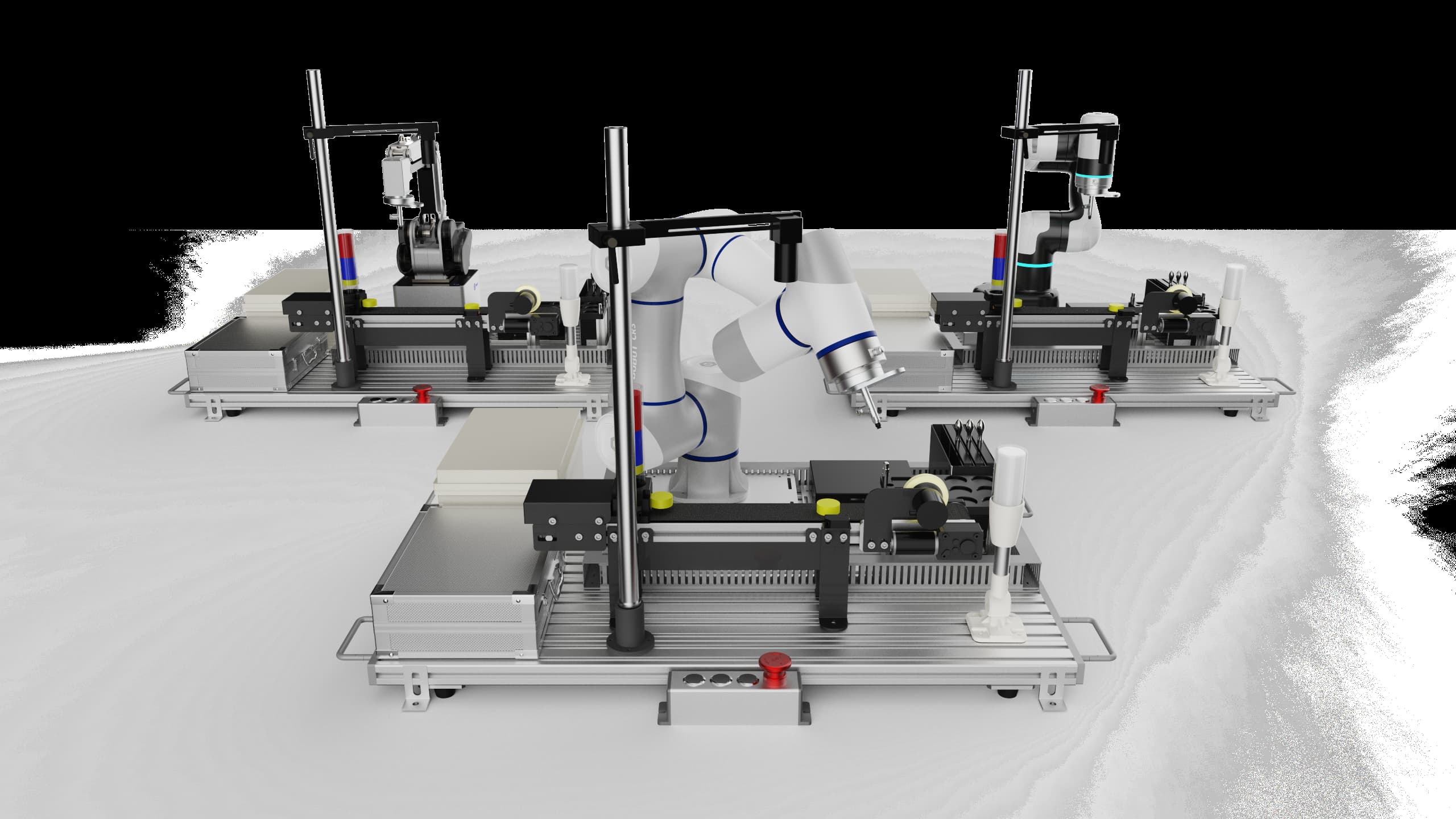

Mobile Robotics Platform STEM Technology Cell

Provides community colleges, vocational schools and technical colleges with the best possible equipment for teaching industrial robotics.

- Mobile platform design fits through standard doorways

- Multi-purpose pneumatic grippers and valves

- Welding platform includes industrial weld equipment

- Workspace overlay provides endless exercises

- 110 VAC single phase power

- Additional options available (2D Cognex vision, QC conveyor, simulation software and other peripherals)

Curriculum

Yaskawa Endorsed Programs for Robotics and STEM Teacher Training

The Motoman Endorsed Robotics Instructor Training (MERIT) Program was developed specifically for educational institutions who have a vision of becoming a Yaskawa Motoman satellite training facility. It is designed to bring the same quality of training, as delivered by the Yaskawa Academy, closer to our installed base.

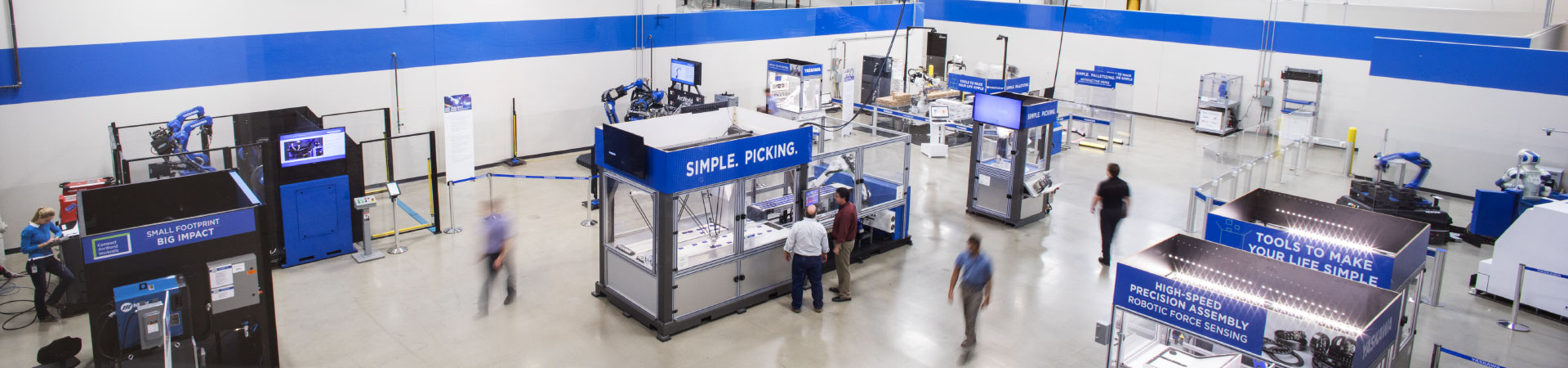

Yaskawa Academy occupies 13,400 sq ft with 78 robots totally dedicated to training. All training is delivered by dedicated and certified instructors. Over 75 different training courses are offered for a wide range of Motoman controllers including NX, FS and DX and the newest YRC1000. Training classes for each controller type include: Operators, Basic Programming, Advanced Programming, Ladder Logic and Maintenance.

All of our training courses and programs undergo a rigorous evaluation procedure and process which adheres to the American National Standards Institute/ International Accreditors for Continuing Education and Training (ANSI/IACET 1-2018 Standard).

The MERIT Program Supports Two Levels of Training:

College Undergraduate

The MERIT Program provides the ability to develop a new program with the focus on robotics, or to expand an existing one. Topics can be customized with any set of objectives in mind.

Industrial User

The MERIT Program offers a method to deliver the exact same training offerings to local manufacturers in a surrounding area. Once an instructor becomes certified in a specific training class, he or she will be able to deliver the same curriculum as Yaskawa Academy. Students will receive the same class material and instruction as if attending Yaskawa Academy. Upon successful completion of any MERIT delivered course, the student will receive a certificate from Yaskawa Motoman. Certificates are endorsed by Yaskawa Motoman, and valid as prerequisites for any future advanced training classes within the respective controller group.

Benefits

- Recognition as a Yaskawa Motoman endorsed satellite training facility

- Students will be awarded a Yaskawa Academy certificate with the International Accreditors for Continuing Education and Training (IACET) CEU logo upon successful completion

- Partnership with a leading robotics company; “creating a better tomorrow”

- Expansion of knowledge base and accessibility of robotics to everyone

- Assignment of a certified robotics instructor to ensure continued success and development of staff

- Utilization of a proven training model and class training materials

- Curriculum development–leave maintenance of the curriculum to us

- Annual audits/visits to ensure your success